Sunday, 16 December 2012

Thursday, 13 December 2012

Profil Manusia

Profil mereka yang MEMPENGARUHI

Mereka bersifat peramah, bijak dalam pergaulan, ramai kawan dan ramai yang suka mendampingi mereka. Mereka ini petah berkomunikasi dan seorang yang bijak bersosial, suka menarik perhatian orang lain untuk terlibat bersama mereka.

Mereka ini cenderung untuk mengekalkan hubungan dengan mewujudkan suasana yang sentiasa

positif. Sifat penyayang dan keprihatinan yang ditunjukkan lebih menyifatkan

mereka ini mementingkan keharmornian.

Namun begitu kadangkala sikap terbuka mereka ini kadangkala memerangkap

diri mereka sendiri.

-RAH-

Monday, 10 December 2012

Lean in Supply Chain

Lean Supply Chain

contribution toward Lean Health Care

Edly Ferdin Ramly

Principal for EFR Management, Malaysia edly@efrmanagement.com

ABSTRACT

Lean systems allow a supply

chain to not only to be more efficient, but also faster. We can get our

sufficient supplies at right time, right quantity without any shortage or

excess inventory with effective lean supply chain. As the culture of lean takes

over the entire supply chain, all links increase their velocity. A culture of

rapid response and faster decisions becomes the expectation and the norm. However

leans supply chain always being left out during lean implementation in health

care.

Keywords: Lean Health care,

Just in time, Value Stream Map

INTRODUCTION

Lean thinking

are applicable anywhere there are processes to improve, including the entire

supply chain. A lean supply chain is one that produces just what and how much

is needed, when it is needed, and where it is needed.

The underlying

theme in lean thinking is to produce more or do more with fewer resources while

giving the end customer exactly what he or she wants. This means focusing on

each product and its value stream. To do this, organizations must be ready to

ask and understand which activities truly create value and which ones are

wasteful. The most important thing to remember is that lean is not simply about

eliminating waste—it is about eliminating waste and enhancing value.

The objectives

of this paper is to discuss the benefit and strategy ti implement lean supply

chain effectives. This synthesis based on single action base research enables

even small supplier or contractors to participate in the results of lean

efforts.

BENEFITS OF LEAN SUPPLY CHAIN

The main issues

in health care is increase of cost in medical supplies. The supplies included scientific

supply, medical supplies, linens, dietary, medical records, Patient

transportation and many more. All this supplies need to be

deliver in many areas in hospital including ward, clinics, laboratory and

theatres.Many supplies are everywhere and duplicate in many

location. Sometime excessive stock will lead to Out-of-date stock, less stock

will have erratic ordering, too many replenishment of supplies.

What benefit

the hospital when the hospital improve the supply chain? The hospital will able

to managed the supply chain effectively hence the expected results are:

•

Reduce purchasing cost

•

Reduce inventory

•

Reduce storage area

•

Improve warehouse control

•

Reduce lead time

•

Transportation cost

•

Reduce

error

A strong supply

chain enables the hospital to align themselves with each other and to

coordinate their continuous improvement efforts. Competitive advantage and

leadership in the global marketplace can only be gained by applying lean

principles to the supply chain. Thought, commitment, planning, collaboration,

and a path forward are required. A lean supply chain is proactive and plans for

the unexpected by positioning all resources for effectiveness. Downturns in

demand can be addressed without layoffs or significant productivity losses. What benefits the

organization as a whole benefits the supply chain.

LEAN SUPPLY CHAIN

STRATEGY

Supply chains

that want to grow and continue to improve must adopt lean. Lean concepts

require an attitude of continuous improvement with a bias for action. The

concepts of lean apply to all elements of the supply chain, including support

departments such as product development, quality, human resources, marketing,

finance, purchasing, and distribution. The challenge is to bring all of these

areas out of their traditional silos and make them work together to reduce

waste and create flow. Duplication and a lack of appropriate and timely

communication run rampant in these traditional organizations. All chain

partners have to be on the same playing field, and the lean concept is intended

to let everyone reach new levels of efficiency and effectiveness. Supply chain

leaders should not delay—it's urgent to act now to implement lean concepts in

the supply chain.

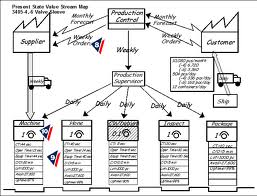

The strategy

relies on VIC strategy. The first strategy is to develop the value stream

mapping (V). The value stream map (VSM) able to identify the process, the

supplier. However the supply chain detail, is not identify in first level and

second level of VSM. Additional information need to be integrate (I) to the

VSM. The detail may included the type of supply required for each process,

quantity required, pull or push system, and supermarket. The final strategy is to

control the supplies.

Figure 1: Material flow symbol (Rother and

Shook, 1999)

CASE STUDY

The

team from Hospital A are eager to implement lean. Almost all the service have been analyses using value

stream map. The first strategy has been completed. However the format of value

stream map, have the problem on identify the supplier. The solution is use the

VSM proposed by Nash and Poling (2008). The supplier sysmbol have eliminate and

start with the “patient”

Figure 2: The example of VSM for

diagnostic imaging

The second strategy was to integrate the

the supply chain information VSM. Most of common VSM don’t have space to

identify the supplies required for the process. There are suggestion to use

simple process mapping but the ideas not able to see the connection of the

supplies to the process and other department. The team decided to used the

bottom of process to list out the supplies for each process. Example during

preparation of patients, all the items are listed and quantity required is

quantified and at the same time the number stock kept and the way of the stock

replenished is added.

The last strategy is to identify the way

to control the stock. The pull with Kanban system and visual management is

always the best solution. But there were some cases where the supplies can be

eliminate at all for example film type of diagnostic change with electronic

imaging. 5S control was implemented and minimum stock especially for consumable

supplies i.e. paper table, drape exam sheet, glove, gauze; medical supplies

i.e. Kenalog, prep pad alcohol etc.

CONCLUSIONS

With VIC (VSM – Integrate - Control) strategy, the lean supply chains have

implemented effectively on the internal stock control. The value stream mapping

provide more visual diagram of the supplies flow in health care process. Since

in health care main focus is patient, and to provide more value to patient,

sometime the stock control not been capture in VSM. The additional integration

was used to capture the supplies and stock current and futire practices. The

next challenge of the hospital is extend the implementation to purchasing,

central store and lean supplier for example on just in time, reduction of batch

size (minimum order quantity) and pull system.

ACKNOWLEDGEMENTS

The author would like to thank EFR

Management, Malaysia Productivity Corporation, National Iranian Productivity

Organization, Asia Productivity Organization, and management and staff of

Hospital A, Hasheminijad Kidney Centre, Tehran, Moheb Hospital, Tehran that provide the financial and resources

support in this research.

REFERENCES

Rother M and Shock J (1999),

“Learning to See”, Lean Enterprise

Institute

Arter D.R. (2008). Mapping

the total value stream mapping”, Productivity Press

Presented in

International Conference on Continuous Value Adding based on Lean Thinking in Hospital Management, Tehran, Iran,

30 Nov – 1 Dec 2011

Friday, 7 December 2012

LEAN - Step 3 Eliminate Waste

Strategi Penghapusan PEMBAZIRAN - Langkah 3 - Menghapuskan pembaziran

Selepas mengenalpasti pembaziran, seperti mana-mana proses penambahbaikan kita perlu mengenalpasti PUNCA mengapa pembaziran itu BERLAKU

Punca yang berkaitan secara langsung adalah kerana TAKUT-TAKUT

Punca yang contribute termasuklah:

Masalah Kualiti

Pekerja tidak mahir

Mencari barang, part, bahan mentah dsbg

Permintaan yang tidak menentu

Set-up mesin/ proses terlalu lama

Kerosakan sistem

Suka pada batch yang besar

Supplier lambat hantar

Kapasiti mesin, tempat dan ruang yang besar

Sebelum kita berbincang tentang beberapa alat (tools) dan teknik yang boleh digunakan, kita tengok apakah HIERARCHY Teknik-teknik penghapusan.

PERTAMA - HAPUSKAN TERUS apa-apa pembaziran yang tidak perlu atau yang boleh di ELAKKAN.

Contohnya, perlu ke kita cetak borang sedangkan sudah ada proses ONLINE

KEDUA - KURANGKAN

Contohnya, perlu ke kita menjalankan proses pengesahan sehingga 3 kali. Mungkin kita boleh hapuskan 2 proses tersebut dan tinggalkan 1

KETIGA - KOMBINEKAN

Kemungkinan kita boleh menggunakan alat (tools yang sesuai) seperti:

Masalah Kualiti - Poka Yoke, FMEA, Jidoka

Pekerja tidak mahir - Multiskill, empowerment etc

Mencari barang, part, bahan mentah dsbg - 5S

Permintaan yang tidak menentu - PULL, KANBAN sistem

Set-up mesin/ proses terlalu lama - SMED

Kerosakan sistem - TPM

Suka pada batch yang besar - One piece flow, looping, relayout etc, Heijunka

Supplier lambat hantar - Pull, JIT, Kanban

Kapasiti mesin, tempat dan ruang yang besar - Kecikkan tempat tu

Kebanyakan alat-alat diatas boleh menabantu mengeliminasi atau mengurangkan PEMBAZIRAN

Selamat mencuba

-CER-

Selepas mengenalpasti pembaziran, seperti mana-mana proses penambahbaikan kita perlu mengenalpasti PUNCA mengapa pembaziran itu BERLAKU

Punca yang berkaitan secara langsung adalah kerana TAKUT-TAKUT

Punca yang contribute termasuklah:

Masalah Kualiti

Pekerja tidak mahir

Mencari barang, part, bahan mentah dsbg

Permintaan yang tidak menentu

Set-up mesin/ proses terlalu lama

Kerosakan sistem

Suka pada batch yang besar

Supplier lambat hantar

Kapasiti mesin, tempat dan ruang yang besar

Sebelum kita berbincang tentang beberapa alat (tools) dan teknik yang boleh digunakan, kita tengok apakah HIERARCHY Teknik-teknik penghapusan.

PERTAMA - HAPUSKAN TERUS apa-apa pembaziran yang tidak perlu atau yang boleh di ELAKKAN.

Contohnya, perlu ke kita cetak borang sedangkan sudah ada proses ONLINE

KEDUA - KURANGKAN

Contohnya, perlu ke kita menjalankan proses pengesahan sehingga 3 kali. Mungkin kita boleh hapuskan 2 proses tersebut dan tinggalkan 1

KETIGA - KOMBINEKAN

Kemungkinan kita boleh menggunakan alat (tools yang sesuai) seperti:

Masalah Kualiti - Poka Yoke, FMEA, Jidoka

Pekerja tidak mahir - Multiskill, empowerment etc

Mencari barang, part, bahan mentah dsbg - 5S

Permintaan yang tidak menentu - PULL, KANBAN sistem

Set-up mesin/ proses terlalu lama - SMED

Kerosakan sistem - TPM

Suka pada batch yang besar - One piece flow, looping, relayout etc, Heijunka

Supplier lambat hantar - Pull, JIT, Kanban

Kapasiti mesin, tempat dan ruang yang besar - Kecikkan tempat tu

Kebanyakan alat-alat diatas boleh menabantu mengeliminasi atau mengurangkan PEMBAZIRAN

Selamat mencuba

-CER-

Thursday, 6 December 2012

LEAN Leadership

Sustaining

and spreading the gains in lean Hospitals: Role of Leadership

Edly Ferdin Ramly

ABSTRACT

Whether you follow

Lean, Six Sigma, or an internal methodology, one of the biggest challenges of

process improvement is ensuring that process changes are adopted

consistently—and sustained— and spread by your organization. How can you

measure how well your process improvements have been adopted? And how can you

monitor activity to ensure process improvements are sustained while identifying

new best practices for continuous improvement. The success factors of lean lies

on lean leadership.

Keywords: Lean Health care, Lean

Leadership

INTRODUCTION

People often equate “Lean” with the tools that are

used to create efficiencies and standardize processes. However, implementing

tools represents at most 20 percent of the effort in Lean transformations. The

other 80 percent of the effort is expended on changing leaders’ practices and

behaviors, and ultimately their mindset. Senior management has an essential

role in establishing conditions that enable that 80 percent of the effort to

succeed. Their involvement includes establishing governance arrangements that

cross divisional boundaries, supporting a thorough, long-term vision of the

organization’s value-producing processes, and holding everyone accountable for meeting

Lean commitments. This is accomplished through regular, direct involvement.

When upper management sets the example, durable Lean success and an

increasingly Lean leadership mindset follow.

Most of the literature on Lean conversions has

focused on implementing the Lean tools (to create flow, establish pull, support just-in-time production, etc.) in

manufacturing (Womack and Jones 1996; Rother and Shook 1998). Some of the

literature has explored Lean tools in healthcare, office settings, or product development

processes (Graban 2008); Critiques of

the tools only focus note that even brilliant use of tools without changes in

culture rarely produces lasting change, or even lasting .There is a missing link in Lean. This missing link

is the set of leadership behaviors and structures that make up a Lean

management system.Lean management bridges a critical divide: the gap between

Lean tools and Lean thinking. Systematic Lean management separates Lean

initiatives that start well but falter from those that sustain initial gains

and deliver further improvement.

In

this paper, we examines the key reasons why process changes often fail to be

sustained in the long term. Explore DIET techniques on how you can track

whether your organization is

really sustaining and spread the lean thinking

and continuous improvement.

FAILURE OF LEAN

IMPLEMENTATION

The lean effort

is consider failed once the organization stop their effort in waste elimination

stop. Stop mean the gain not been sustain and the implementation not been

spread. The main reason of failure are due to:

1. Purpose – The purpose of lean initiative have not been

clearly defined. In many cases, the organization adopted the lean just because

it is “the best menu of the day”.

2.

Process – The

process of the lean implementation not been plan, do, check and action. Yet, my own observations say this is

precisely the thing that most companies can’t seem to do. Why? Surely one major

reason for this is the way we lead and;

3. People – Employees didn’t buy in the initiative.

THE ROLES OF THE LEAN

LEADER

For hospital-wide Lean initiative to succeed, leaders at three

organizational levels must play complementary roles. This overlap reinforces

continuity of support for new practices throughout the organization, e.g.,

disciplined adherence, attention to process performance at intersections, and

gemba walking (which takes managers to the front lines to look for improvement

opportunities). This continuity maintains the internal integrity of Lean tool

implementations and the Lean management system.

Senior leaders play a central role in Lean

management. Their contributions are essential in:

1. Developing and implementing structures and

processes that anticipate and respond to the difficulties of a Lean initiative

that crosses internal boundaries;

2. Increasing the odds that process improvements

survive the transition from project mode to ongoing process and Creating

conditions in which a sustainable Lean culture of continuous improvement can

develop.;

3. Establishing and maintaining new,

process-focused measures along side conventional measures of results;

4. Transforming commitments to change into actual

change, supporting and sustaining new behaviors and practices;

The leader’s job at Toyota get each person to take initiative to solve problems and improve

his or her job. The Leader’s job is to

develop his or her people

spirit of Lean Mentorship. “If the learner hasn’t learned, the teacher hasn’t

taught”

Figure 1: Example of leadership model at

Toyota

Leadership at Toyota change from managing numbers to managing the process.Leaders at Toyota, like leaders anywhere,

want to see measurable results. But they know that the financial result is a result

of a process. They also realize that the financial results reflect

the past performance of that process. Far better is to create a process

that can be managed right NOW.

Leadership at Toyota also change from Problem-hiding to Problem-solving. All actions at Toyota revolve around planning

and problemsolving. It is assumed that there will be problems, that everything

will not go according to plan. “No problem is problem.” For the system to work,

problems must be exposed and dealt with forthrightly. Hiding problems will

undermine the system. Leadership at

Toyota utilised P-D-C-A. Toyota would say this is essentially the

P-D-C-A management cycle they learned from Dr. Deming.

Chairman Cho of Toyota:

Three Keys to Lean Leadership

- Go See - “Sr. Mgmt. must spend time on the plant floor.

- Ask Why - “Use the “Why?” technique daily.

- Show Respect. “Respect your people.”

In the early days of lean

implementation, the leader should allowed to just try things, to make mistakes and

learn from them. That’s the spirit that required in lean. “Continuous

improvement comes from making mistakes and learning from them." “It is a

mistake to suppose that men succeed through success; they much oftener succeed through

failures. Precept, study, advice, and example could never have taught them so

well as failure has done.”

CONCLUSIONS

Lean leadership is the key toward lean success.

The leader need to define the clear purpose of lean and ensure the first

project is the successful by giving full support and resources. Focus on

measure should be established based on process and transformed the commitment

in term coaching, education and respects.

ACKNOWLEDGEMENTS

The author would like to thank EFR

Management, Malaysia Productivity Corporation, National Iranian Productivity

Organization, Asia Productivity Organization, and management and staff of

Hospital A, Hasheminijad Kidney Centre, Tehran, Moheb Hospital, Tehran that provide the financial and resources

support in this research.

REFERENCES

Rother M and Shock J (1999),

“Learning to See”, Lean Enterprise

Institute

Graban

(2008), “Lean Hospitals: Improving Quality, Patient Safety, and Employee

Satisfaction “, Productivity Press

Presented at - International Conference on Continuous Value Adding based

on Lean Thinking in Hospital Management, Tehran, Iran,

30 Nov – 1 Dec 2011

Edly Ramly ã2011 www.efrmanagement.com and www.efrcertification.com

Tuesday, 4 December 2012

LEAN - Step 2 Identify Waste

Strategi Penghapusan PEMBAZIRAN - Langkah 2 - Mengenalpasti pembaziran

Untuk mengenalpasti pembaziran, ada beberapa alat (tools) dan teknik yang boleh digunakan. Tanpa Tools dan teknik, proses penegnalpastian boleh dilakukan juga. Tetapi ia mungkin tidak berapa efektif dan sukar untuk mendapatkan gambaran tentang dimana pembaziran berlaku, kenapa ia berlaku dan "how severe is it"

Teknik yang terkenal adalah teknik "Value Stream Mapping" yang diperkenalkan oleh Mike dan Rother didalam buku bertajuk "Learning to See".

Tool 1

Value stream mapping menngunakan kombinasi:

1) Carta aliran proses

2) Aliran maklumat

3) Maklumat berkaitan

- Masa Proses

- Masa Menunggu

- Jumlah invetori sebelum dan selepas proses

- Yield (ataupun Complete and Accurate)

- Bilangan tenaga kerja

dan berbagai lagi

Tool 2 = Process Mapping

Proses mapping adalah teknik analisa yang lebih detail untuk MASA sesuatu proses dijalankan. Teknik ini selalunya digunakan apabila proses di dalam VSM menunjukkan masa yang panjang diperlukan untuk menyiapkan sesuatu.

Proses mapping akan memecahkan proses kepada proses-proses yang lebih kecil supaya setiap proses itu boleh dikenalpasti pembazirannya.

Tool 3 = Spaghetti Diagram

Antara tools yang disukai ramai adalah spaghetti diagram. Diagram ini digunakan untuk mengenalpasti waste of motion dan conveyance didalam satu-satu kawasan.

Ada beberapa lagi tools yang boleh digunakan. Tetapi yang penting adalah pembaziran dapat dikenalpasti, digambarkan dan mudah untuk dibentangkan.

Seterusnya pembaziran ini perlu di labelkan. Biasanya dilabelkan dengan bintang letupan. Langkah seterusnya ialah... HAPUSKAN pembaziran tersebut

-CER-

Untuk mengenalpasti pembaziran, ada beberapa alat (tools) dan teknik yang boleh digunakan. Tanpa Tools dan teknik, proses penegnalpastian boleh dilakukan juga. Tetapi ia mungkin tidak berapa efektif dan sukar untuk mendapatkan gambaran tentang dimana pembaziran berlaku, kenapa ia berlaku dan "how severe is it"

Teknik yang terkenal adalah teknik "Value Stream Mapping" yang diperkenalkan oleh Mike dan Rother didalam buku bertajuk "Learning to See".

Tool 1

Value stream mapping menngunakan kombinasi:

1) Carta aliran proses

2) Aliran maklumat

3) Maklumat berkaitan

- Masa Proses

- Masa Menunggu

- Jumlah invetori sebelum dan selepas proses

- Yield (ataupun Complete and Accurate)

- Bilangan tenaga kerja

dan berbagai lagi

Tool 2 = Process Mapping

Proses mapping adalah teknik analisa yang lebih detail untuk MASA sesuatu proses dijalankan. Teknik ini selalunya digunakan apabila proses di dalam VSM menunjukkan masa yang panjang diperlukan untuk menyiapkan sesuatu.

Proses mapping akan memecahkan proses kepada proses-proses yang lebih kecil supaya setiap proses itu boleh dikenalpasti pembazirannya.

Tool 3 = Spaghetti Diagram

Antara tools yang disukai ramai adalah spaghetti diagram. Diagram ini digunakan untuk mengenalpasti waste of motion dan conveyance didalam satu-satu kawasan.

Ada beberapa lagi tools yang boleh digunakan. Tetapi yang penting adalah pembaziran dapat dikenalpasti, digambarkan dan mudah untuk dibentangkan.

Seterusnya pembaziran ini perlu di labelkan. Biasanya dilabelkan dengan bintang letupan. Langkah seterusnya ialah... HAPUSKAN pembaziran tersebut

-CER-

LEAN - Case Study - Sistem Penyampaian 1

Buat masa ini, banyak initiatif yang cuba dijalankan oleh kerajaan untuk menjadikan operasi mereka leboih lean. Sebelum saya kongsi beberapa case study lain yang diutara semasa sessi kurus lean beberapa agensi kerajaan yang lain, rencana ini dipetik daripada:

http://pmr.penerangan.gov.my/index.php/component/content/article/79-mengenai-kerajaan/8577-sistem-penyampaian-kerajaan-.html

Kerajaan sentiasa mengambil perhatian dan berusaha untuk meningkatkan

sistem penyampaian perkhidmatan semua kementerian dan agensi sektor awam.

Pelbagai tindakan susulan telah dilaksanakan dengan memberi penekanan kepada

lima (5) aspek berikut, iaitu:

· pembangunan Sumber Manusia;

·

pemantapan sistem dan prosedur kerja;

·

pengemaskinian undang-undang dan akta;

·

penggunaan ICT dalam penyampaian perkhidmatan; dan

·

pelaksanaan transformasi organisasi secara menyeluruh.

Selain daripada usaha berterusan seperti yang tersebut, mulai tahun 2007, kerajaan telah mengambil inisiatif untuk menubuhkan Pasukan Petugas Khas Pemudahcara Perniagaan, yang dikenali secara ringkas sebagai PEMUDAH. |

PEMUDAH merupakan satu perkongsian

bistari (smart partnership) di antara kerajaan dan sektor swasta yang diwakili

oleh Federation of Malaysian Manufacturers (FMM). PEMUDAH telah berjaya

menghasilkan beberapa pembaharuan dan peningkatan kecekapan penyampaian dengan

memudahcarakan prosidur dan tempoh pengurusan..

Contoh 1 - Tempoh pengeluaran

passport dari beberapa minggu sehingga hanya dua (2) jam yang merupakan satu

rekod sedunia.

Contoh 2:

Secara khusus, mengenai pemantapan pengurusan kewangan, sukacita dimaklumkan bahawa, melalui Surat Pekeliling Perbendaharaan Bil. 7 Tahun 2006, semua agensi Kerajaan dikehendaki menguruskan pembayaran bil dan tuntutan tidak lewat dari 14 hari dari tarikh ianya diterima. Berdasarkan pemantauan rapi yang dilaksanakan, prestasi agensi-agensi Kerajaan dalam menguruskan pembayaran bil dan tuntutan telah bertambah baik. Bagi tempoh 1 hingga 31 Oktober 2009 misalnya, prestasi pengurusan bil bagi 24 Kementerian adalah seperti berikut:

* Pembayaran dalam tempoh 14 hari ialah 96.67% dengan melibatkan 446,147 bil, di mana 86.66% mencapai tahap pembayaran dalam tempoh 7 hari yang melibatkan 391,858 bil

Secara khusus, mengenai pemantapan pengurusan kewangan, sukacita dimaklumkan bahawa, melalui Surat Pekeliling Perbendaharaan Bil. 7 Tahun 2006, semua agensi Kerajaan dikehendaki menguruskan pembayaran bil dan tuntutan tidak lewat dari 14 hari dari tarikh ianya diterima. Berdasarkan pemantauan rapi yang dilaksanakan, prestasi agensi-agensi Kerajaan dalam menguruskan pembayaran bil dan tuntutan telah bertambah baik. Bagi tempoh 1 hingga 31 Oktober 2009 misalnya, prestasi pengurusan bil bagi 24 Kementerian adalah seperti berikut:

* Pembayaran dalam tempoh 14 hari ialah 96.67% dengan melibatkan 446,147 bil, di mana 86.66% mencapai tahap pembayaran dalam tempoh 7 hari yang melibatkan 391,858 bil

* Pembayaran lewat iaitu melebihi 14 hari ialah 1.33% yang

melibatkan 6,030 bil

Contoh 3:

Contoh 3:

Untuk meningkatkan lagi kecekapan dalam menguruskan surat-menyurat,

Kerajaan telah menetapkan dalam para 6.10 Pekeliling Perkhidmatan Bilangan 5

Tahun 2007 bahawa semua surat yang diterima hendaklah diambil tindakan segera.

Sekiranya surat itu memerlukan jawapan segera, ia hendaklah dibalas dalam masa

yang singkat. Sekiranya jawapan segera tidak dapat diberikan, penulis surat itu

hendaklah dimaklumkan melalui surat akuan terima yang menyatakan bahawa

tindakan sedang diambil dan jawapan yang lengkap akan disusuli dalam satu

jangka masa yang dinyatakan.

Contoh 4: Lesen Perniagaan

Sila rujuk Blog MPC

http://blog.mpc.gov.my/index.php/2011/07/12/meningkatkan-penyampaian-perkhidmatan-sektor-awam-melalui-pemodenan-lesen-perniagaan?blog=6

Kerajaan akan terus berusaha gigih, dengan menggunakan kaedah pengurusan dan teknologi yang bersesuaian untuk terus meningkatkan lagi mutu system penyampaian sektor awam supaya lebih responsive serta dapat memenuhi kehendak rakyat jelata. Dalam pada ini, kerajaan sentiasa mengalu-alukan dan menghargai maklumbalas dan teguran secara spesifik daripada orang awam, dan khasnya daripada wakil rakyat.

-CER-

Monday, 3 December 2012

LEAN - Step 1 Awareness

Strategi pertama untuk perlakasanaan LEAN adalah kesedaran tentang WASTE ataupun PEMBAZIRAN.

Ramai yang tidak sedar, pembaziran ada didepan mata. Banyak juga terfikir tentang pembaziran elektrik, penjimatan kos dan sebagainya.

Ada pembaziran yang sudah menjadi akar umbi, manakala ada juga yang baru nak bermula.

Kita perlu faham sebelum lain-lain pembaziran berlaku, ia berlaku kerana ada PROSES yang tidak perly DILAKUKAN.

PROSES TIDAK PERLU

1) Termasuklah proses yang tidak diperlukan oleh PELANGGAN. Dalam erti kata lain, pelanggan tak kisah, kita buat ataupun tak buat.

- MENUNGGU

- PERGERAKAN DALAM PEJABAT

- MENYEMAK BERULANG-ULANG mahupun approval atau birokrasi

2) Proses yang tidak diperlukan oleh ORGANISASI. Selalunya proses ini dicipta kerana perasaan TAKUT-TAKUT

Contohnya -

takut-takut salah... jadi kena la check banyak kali

takut-takut tak cukup... beli barang banyak

takut-takut pelanggan minta

takut-takut BOSS marah

taku-takut mesin rosak

takut-takut ambik masa ynag lama untuk set-up

dan macam-macam takut-takut

SEMUA PROSES INI TIDAK MENAMBAH NILAI dan kita perlu sedar yang proses ini adalah PEMBAZIRAN.

-CER-

Ramai yang tidak sedar, pembaziran ada didepan mata. Banyak juga terfikir tentang pembaziran elektrik, penjimatan kos dan sebagainya.

Ada pembaziran yang sudah menjadi akar umbi, manakala ada juga yang baru nak bermula.

Kita perlu faham sebelum lain-lain pembaziran berlaku, ia berlaku kerana ada PROSES yang tidak perly DILAKUKAN.

PROSES TIDAK PERLU

1) Termasuklah proses yang tidak diperlukan oleh PELANGGAN. Dalam erti kata lain, pelanggan tak kisah, kita buat ataupun tak buat.

- MENUNGGU

- PERGERAKAN DALAM PEJABAT

- MENYEMAK BERULANG-ULANG mahupun approval atau birokrasi

2) Proses yang tidak diperlukan oleh ORGANISASI. Selalunya proses ini dicipta kerana perasaan TAKUT-TAKUT

Contohnya -

takut-takut salah... jadi kena la check banyak kali

takut-takut tak cukup... beli barang banyak

takut-takut pelanggan minta

takut-takut BOSS marah

taku-takut mesin rosak

takut-takut ambik masa ynag lama untuk set-up

dan macam-macam takut-takut

SEMUA PROSES INI TIDAK MENAMBAH NILAI dan kita perlu sedar yang proses ini adalah PEMBAZIRAN.

-CER-

Sunday, 2 December 2012

Apa itu LEAN?

Perkataan “Lean” menjadi

terkenal apabila Womack dan Jone menerbitkan buku “Lean Thinking” pada tahun

1996. Perkataan Lean digunakan bukan

bermaksud ... sandar. Jika kita lihat kamus bahasa Inggeris, Lean juga

bermaksud KURUS. Kaitan kurus, adalah menjalankan aktiviti dengan secara SLIM dan tak berlemak.

Lean dalam konteks kualiti dan kos bermaksud “EFISYEN”.

Efisyen bermaksud menjalankan aktiviti dengan mengoptimakan sumber, termasuklah

masa, sumber manusia, tenaga dan juga kewangan. Dalam masa yang sama, memenuhi

kehendak pelanggan dan meningkatkan kepuasan pelanggan.

Apakah MATLAMAT utama LEAN

Matlamat utama lean ada MENGHAPUSKAN pembaziran. Sbelum

perkataan lean digunakan, teknik yang sama digunakan oleh Lean adalah TPS

ataupun Toyota Production System. TPS telah diamalkan oleh pihak Jepun semenjak

tahun 60 an kerana mereka kekurangan sumber, termasuklah tanah dan sumber asli.

Jadi mereka kena memikirkan bagaimana untuk mengoptimakan sumber-sumber yang

ada.

Apakah PEMBAZIRAN

(WASTE) yang ada didalam operasi

Teknik VAVE (value analysis dan value engineering)

memfokuskan rekabentuk dan pembangunan

(design dan development) untuk produk, manakala LEAN memfokuskan kepada

operasi.

Ada TIGA jenis pembaziran

proses yang mudah untuk di INGATI iaitu

WAIT (TUNGGU)

CHECK (SEMAK)

MOVE (GERAK)

Manakala TOYOTA pula memperkenalkan 7 jenis Pembaziran

iaitu, Wait, Over-produce, Motion, Rework, over-proses, inventory dan

conveyance (ataupun transpirt). Ada yang menambah pembaziran Maklumat

)Information) dan berbagai lagi.

Apakah STRATEGI Lean.

Jika mengikut Lean

Thinking” ada 5 strategi. Tetapi saya lebih suka meringkaskan strategi LEAN

kepada TIGA iaitu:

1 1) SEDAR wujudnya PEMBAZIRAN

2) KENALPASTI Pembaziran itu dimana

3) HAPUSKAN atau KURANGKAN pembaziran tersebut

Ada berbagai teknik dan alat (tools) yang boleh digunakan

sperti menggunakan VSM, Poka YOKE, 5S dan lain-lain lagi.

SUDAHKAN anda melaksanakan LEAN. Keran apembaziran itu

adalah AMALAN SYAITAN

Salam hormat dari saya

\

-CER-

Di Sedenak, (untuk berfikir

sejenaka) Kulai

Workshop LEAN di Suzhou - Tahun 2001 kot

He he he... terjumpa gambar lama. Dalam banyak-banyak worksyop LEAN, ni je gambar yang jumpa... macam kelakar pulak tengok gmbar muda-muda dulu...

Dulu buat worksyop, kena hand-on sekali..

Entah faham ke tak pakcik ni...

Tangga buluh tu... he he

InsyaAllah, saya kongsikan apa itu Lean dan bagaimana melaksanakan lean...

-CER-

Dulu buat worksyop, kena hand-on sekali..

Entah faham ke tak pakcik ni...

Tangga buluh tu... he he

InsyaAllah, saya kongsikan apa itu Lean dan bagaimana melaksanakan lean...

-CER-

MINGGU LEAN

Minggu ni, saya ingin berkongsi sedikit tentang LEAN. Lean adalah antara bidang kepakaran saya selepas audit sistem pengurusan.

Lean antara antara bidang kerjaya saya yang pertama setelah dilantik sebagai Pegawai Promosi Lean pada tahun 2000. Walaupun sebelum itu saya tidak pernah dengar tentang Lean, saya bertuah kerana diberi kepercayaan untuk mempromosikan Lean untuk TRW (sebelum ini dikenali sebagai LUCAS) bersama mentor saya Mr Tom Draper daripada TRW US dan juga sahabat darupada plant-plant TRW yang lain termasuklah En Halim Baharom daripada TRW Bkt Beruntung, Ji Hong daripada Suzhou dan ramai lagi sahabat-sahabat yang lain dari seluruh pelusuk dunia.

Syukor, pada tahun lepas, saya bersama MPC Wilayah Pantai Tinur dapat melancarkan program LEAN kepada PKNP (PErbadanan Kemajuan Negeri Pahang) dan kemudian bersama-sama dengar pakar-pakar Lean yang lain daripada Jepun untuk bersama-sama menjadi mentor dan speaker untuk Lean Seminar untuk PENGURUSAN HOSPITAL di Iran.

Tahun ini, saya dapat bersama-sama dengan pengarah dan pegawai-pegawai MPC (Malaysia Productiviti Corporation) untuk berkongsi dan membangun pakar serta modul berkaitan Lean.

Minggu ini pula dalah minggu yang istemewa kerana saya dapat bersama-saya dengan Pengarah dan kakitangan Pejabat Tanah dan Galian negeri Perak untuk Taklimat Lean pada perhimpunan PTG PErak kali ke-8. Selepas itu saya berkongsi pengalaman dengan kakitangan Pejabat SUK negeri Pulau Pinang di Dewan Seri Pinang untuk sessi kursus lean.

InsyaAllah, saya akan kongsikan jugak, idea perlaksanaan lean dalam penambahbaikan Sistem Penyampaian PErkhimatan Awam. Mula-mula saya kan kongsikan apakah itu Lean.

Selamat membaca.

-CER-

29 Nov 2012

Dewan Sri Pinang, Pulau Pinang

Lean antara antara bidang kerjaya saya yang pertama setelah dilantik sebagai Pegawai Promosi Lean pada tahun 2000. Walaupun sebelum itu saya tidak pernah dengar tentang Lean, saya bertuah kerana diberi kepercayaan untuk mempromosikan Lean untuk TRW (sebelum ini dikenali sebagai LUCAS) bersama mentor saya Mr Tom Draper daripada TRW US dan juga sahabat darupada plant-plant TRW yang lain termasuklah En Halim Baharom daripada TRW Bkt Beruntung, Ji Hong daripada Suzhou dan ramai lagi sahabat-sahabat yang lain dari seluruh pelusuk dunia.

Bersama pakar-pakar LEan daripada APO

Tahun ini, saya dapat bersama-sama dengan pengarah dan pegawai-pegawai MPC (Malaysia Productiviti Corporation) untuk berkongsi dan membangun pakar serta modul berkaitan Lean.

Minggu ini pula dalah minggu yang istemewa kerana saya dapat bersama-saya dengan Pengarah dan kakitangan Pejabat Tanah dan Galian negeri Perak untuk Taklimat Lean pada perhimpunan PTG PErak kali ke-8. Selepas itu saya berkongsi pengalaman dengan kakitangan Pejabat SUK negeri Pulau Pinang di Dewan Seri Pinang untuk sessi kursus lean.

InsyaAllah, saya akan kongsikan jugak, idea perlaksanaan lean dalam penambahbaikan Sistem Penyampaian PErkhimatan Awam. Mula-mula saya kan kongsikan apakah itu Lean.

Selamat membaca.

-CER-

29 Nov 2012

Dewan Sri Pinang, Pulau Pinang

Wednesday, 28 November 2012

KKK - Berkampung di Penang

Kualiti Kedai Kopi... minggu ni lepak 3 hari di George Town, Penang, Malaysia. Biasa dok kat Juru, Prai, kali ni dok kat pusat bandar. Apa-apa pun tahniah buat skuad Malaysia, dapat menundukkan Laos 4-1 sebentar tadi, semoga next game... lagi kelas. Balik ke cerita Penang tadi, ada beberapa perkara yang best kat sini:

1) Nasi Kandar Beratuq memang kick

2) Tourist boleh tahan ramai (ekonomi dan income sure baguih punya)

3) Dapat pakai Penang Free Wifi (jimat data pakej aku)

4) Kali pertama bagi training untuk Pejabat SUK untuk perlaksanaan LEAN (team diorang memang proaktif, banyak idea penambahbaikan sistem penyampaian diterima oleh mereka - Aku orang Johor pun tak pernah kena jemput utk cadangkan perlaksanaan lean utk state administration)

5) dan ada byk agi yang best

Cuma ada sikit pandangan, untuk penambahbaikan KUALITI hidup masyarakat kat sana:

1) Sistem pengangkutan awam, kalau ada sistem MRT ke, monorail ke lagi baguih. Yang penting dari seberang ke pusat2 utama di Pulau. Buat jambatan kedua pun tak selesai masalah jam, tambahlah berapa banyak lebuhraya pun takkan settle.

2) Pejabat pentadbiran negeri, termasuklah SUK, DUN elok buat kat tanah besar, seperti Bertam ke. Georgetown patut fokus kepada pelancungan heritage, bukan pentadbiran negeri.

3) Lepak kat Jalan Masjid Kapitan Kling, jumpa banyak homeless dan pengemis. Lebih baik, bawak diorang gi pusat shelter yang bersesuaian. Merosakkan imej bandar jek dan jugak negeri.

4) Tempat pejalan kaki, longkang boleh diperbaiki lagi... banyak yang tiba-tiba hilang arah (negara maju biasanya tempat pejalan kaki diorang detail dan tak hilang tiba-tiba)...

Ni je yang terlintas malam ni.

Blurp.. sendawa lepas bedal nasik kandar lepas tengok bola tadi.... selamat malam semua

-CER-

Dari kota heritage Georgetown Penang

1) Nasi Kandar Beratuq memang kick

2) Tourist boleh tahan ramai (ekonomi dan income sure baguih punya)

3) Dapat pakai Penang Free Wifi (jimat data pakej aku)

4) Kali pertama bagi training untuk Pejabat SUK untuk perlaksanaan LEAN (team diorang memang proaktif, banyak idea penambahbaikan sistem penyampaian diterima oleh mereka - Aku orang Johor pun tak pernah kena jemput utk cadangkan perlaksanaan lean utk state administration)

5) dan ada byk agi yang best

1) Sistem pengangkutan awam, kalau ada sistem MRT ke, monorail ke lagi baguih. Yang penting dari seberang ke pusat2 utama di Pulau. Buat jambatan kedua pun tak selesai masalah jam, tambahlah berapa banyak lebuhraya pun takkan settle.

2) Pejabat pentadbiran negeri, termasuklah SUK, DUN elok buat kat tanah besar, seperti Bertam ke. Georgetown patut fokus kepada pelancungan heritage, bukan pentadbiran negeri.

3) Lepak kat Jalan Masjid Kapitan Kling, jumpa banyak homeless dan pengemis. Lebih baik, bawak diorang gi pusat shelter yang bersesuaian. Merosakkan imej bandar jek dan jugak negeri.

4) Tempat pejalan kaki, longkang boleh diperbaiki lagi... banyak yang tiba-tiba hilang arah (negara maju biasanya tempat pejalan kaki diorang detail dan tak hilang tiba-tiba)...

Ni je yang terlintas malam ni.

Blurp.. sendawa lepas bedal nasik kandar lepas tengok bola tadi.... selamat malam semua

-CER-

Dari kota heritage Georgetown Penang

Sunday, 18 November 2012

Quality 1st - Defining Quality

There are few interesting statement on Quality on one of the factory that I visit i.e.

"MAKE PEOPLE FIRST BEFORE MAKE PRODUCT"

"Imagine Quality without U and I" ............... QALTY ... some people say it is FAULTY

U (you) and I mean the quality cannot be achieved without people. That why the definition of quality should start with:

ATTITUTE

APTITUTE (KNOWLEDGE)

SPECS/ STANDARDS

CUSTOMER SATISFACTION

Just think about it.... Good night

-CER-

"MAKE PEOPLE FIRST BEFORE MAKE PRODUCT"

"Imagine Quality without U and I" ............... QALTY ... some people say it is FAULTY

U (you) and I mean the quality cannot be achieved without people. That why the definition of quality should start with:

ATTITUTE

APTITUTE (KNOWLEDGE)

SPECS/ STANDARDS

CUSTOMER SATISFACTION

Just think about it.... Good night

-CER-

Subscribe to:

Posts (Atom)

.jpg)